-

-

Space-saving bed

- Back

-

-

-

-

-

-

-

High sleeper bed

- Back

-

-

1-seater high sleeper bed

-

-

-

2-seater high sleeper bed

-

-

-

Ottoman bed

- Back

-

-

Single ottoman bed

-

-

-

Double ottoman bed

-

-

-

Bedroom furniture

-

Office furniture

- Back

-

-

-

Cube furniture

- Good deals

- Our guides

Blog categories

Popular posts

Behind the scenes of the making of a mezzanine bed at ABC Meubles

Aren't you curious to know how your furniture was made?

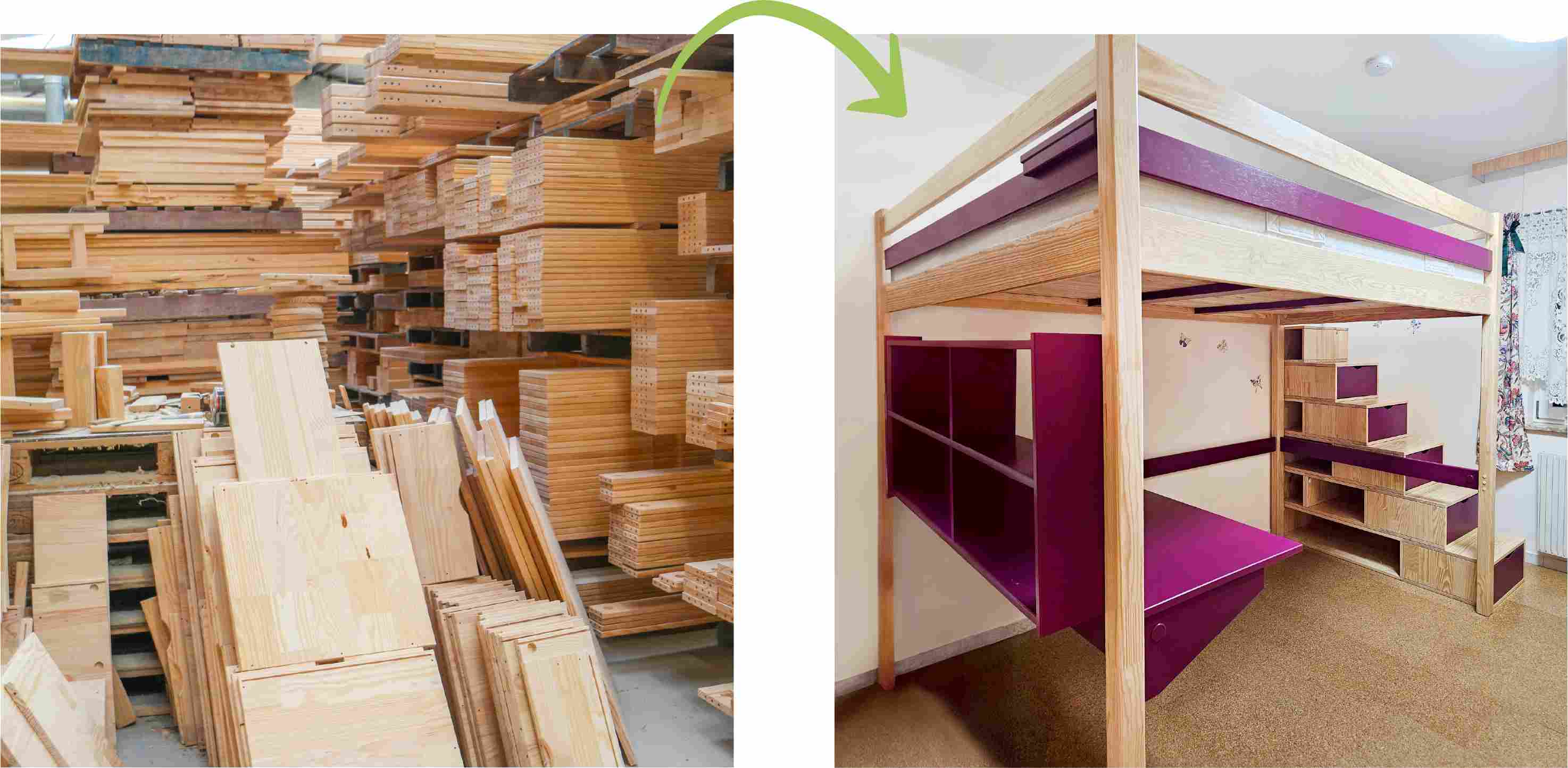

ABC Meubles opens the doors of its workshop to show you how a Sylvia two-tone 140x200 mezzanine bed is made.

For over 30 years, we have been putting our expertise at the service of our customers by offering quality Made in France furniture. By capitalising on our know-how acquired over the years, we offer you durable furniture, meticulously designed to meet your needs and enhance your living space, like our Sylvia mezzanine bed for example.

Our team will take you behind the scenes of the making of a 2-seater loft bed and show you the fascinating stages that transform raw materials into a unique and elegant piece.

Step 1: Sanding the boards

Before passing through the expert hands of our team, the pieces of wood arrive straight from the Landes region of France, to the desired dimensions. It should be noted that 100% of the Sylvia mezzanine bed is made from certified solid pine.

To ensure the surface is smooth to the touch, each part of the mezzanine bed is meticulously sanded, a task Anthony performs with a certain expertise.

His skill at this stage, coupled with high-performance equipment, guarantees impeccable results!

The other parts are sanded by hand, using a sanding bench.

Step 2: Drilling the mortises and fitting the inserts

To assemble the various parts of the mezzanine bed in a solid and consistent manner, the first step is to drill precise holes, also known as mortises, in the posts and sides. This operation requires meticulous precision to ensure that the components fit perfectly when assembled.

Then, to guarantee optimum stability and strength, it is essential to install inserts to hold the studs. This technique provides a secure and durable clamping, ensuring the solidity of the structure as a whole.

In this crucial phase, Philippe excels with his unrivalled know-how and expertise. His mastery of these fastening techniques is remarkable, making him an essential pillar in the creation of a top-quality mezzanine bed.

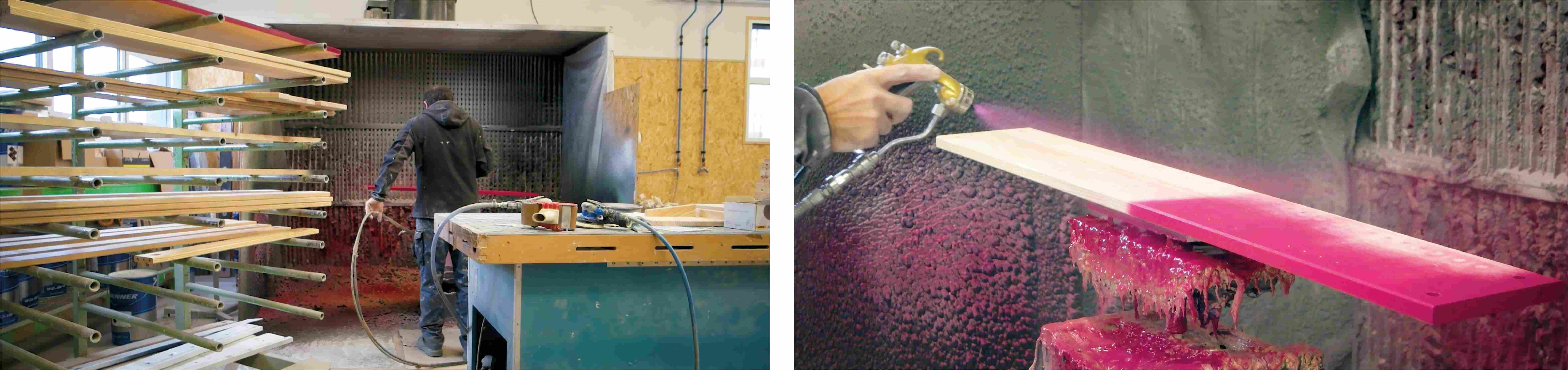

Step 3: finishing

Before the varnish is applied, the parts of the furniture are sanded to ensure the varnish adheres properly. This is where Alban's expertise comes into play, ensuring that each element is treated with care and precision.

Then comes the application of the varnish, whether coloured or transparent.

Our varnish is water-based, solvent-free and VOC-free.

At ABC Meubles, we use 2 techniques:

- By hand, when there are only a few parts to varnish, by Loïc, a true master of the spray gun.

- By robot, when there is a large quantity to be varnished in the same colour, with careful installation of the parts by Danny.

Whether it's Loïc's expert hand or the technological precision of the robot, every step is meticulously executed to guarantee an impeccable finish and lasting protection for the furniture.

Step 4: packaging

Each item, meticulously crafted and inspected in our workshop, is now ready to be dispatched and delivered to your home.

Careful packaging ensures that your furniture is well protected during transport to your home. A quality control check before departure ensures that each item is properly inserted into your parcel and carefully packed.

It is in this art of packing that Céline and Clément excel, reigning as true masters of the domain.

Want to find out more?

Watch the video below showing how this two-tone loft bed is made.

This is how the secrets of making a mezzanine bed at ABC Meubles are revealed.

We hope this immersion has helped you understand our team's unwavering commitment to quality and French craftsmanship.

Every step of the way, every technique used, is testament to our dedication to bringing you quality Made in France furniture.

We are proud to share this adventure with you, and hope that it reinforces your confidence in ABC Meubles.

Related posts

.jpg) Optimising space

Optimising space

.jpg) Wood is trendy

Wood is trendy

.jpg) Maintaining Wooden Furniture

Maintaining Wooden Furniture

Facebook comment